Discover how the Gilbert Grizzly MultiGrip allowed Foundiz you to work in the most challenging conditions with success.

Renewed waterways for a more sustainable transportation in Benelux

Inland shipping is a reliable and durable way of transportation and is growing compared to traditional transport of containers by truck. In fact, one vessel of 4.500 tons has the same capacity as 220 trucks! To create a better passage for these ships, the connection between the river Schelde in Belgium and the Seine river (coming from France) is being improved.

This will help economic growth in central Europe and the project is partly financed by the European Union.

Bridges are being renewed to allow the passage of vessels with 3 layers of containers. The locks are made bigger to create space for ships up to 190 meters long and 11.4 meters wide.

https://www.seineschelde.be/projecten

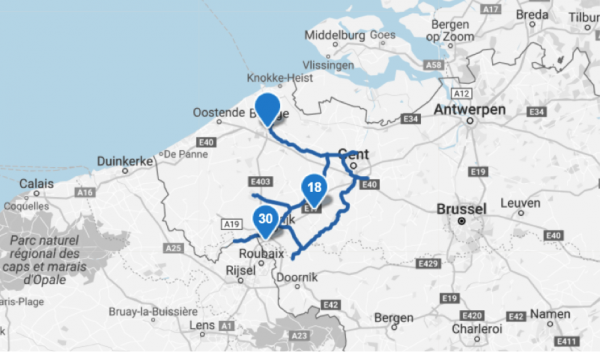

This complete project consists of a total of 7 waterways. These waterways are a network in the Benelux (Belgium, Luxemburg and the Netherlands) and create a better coastal connection for all countries involved.

Projects like these are no longer limited to a better infrastructure but also create more opportunities for nature to adopt and grow. Old areas are restored and deepened so the original character of the river is brought back. Special preparations for fish are made so they can breed and stay during the winter period. Special fish passage places are being created.

For the river bank and bridge renovation in the town Komen-Waasten the Belgium contractor came across a challenge : 12 m long sheetpiles had to be installed underneath the existing bridge which was in full operation. The river, of course, was open for transport during the installation of the sheet piles. All of these space and height restrictions, made our Gilbert Grizzly MultiGrip an evident choice. Foundiz, our distributor, was contacted by the contractor and offered their triple bloom excavator with an MG-90 attached to it. With the MG-90, the double Z piles were installed in sections of only 2 meters long due to the height restriction. After installing a number of these double Z piles the next sections were accurately positioned and welded before the installation of the next sections could proceed. All of this work was carried out from a barge underneath the bridge.