Planer Retrofits at Crabbe Lumber

While Gilbert is widely recognized for its high-speed planer equipment, we also offer upgrade solutions for planers of other brands. These include:

- Electric Motorization retrofits

- Automatic Cutterhead Positioning Systems

- Infeed Table improvements

- And many more custom retrofit options

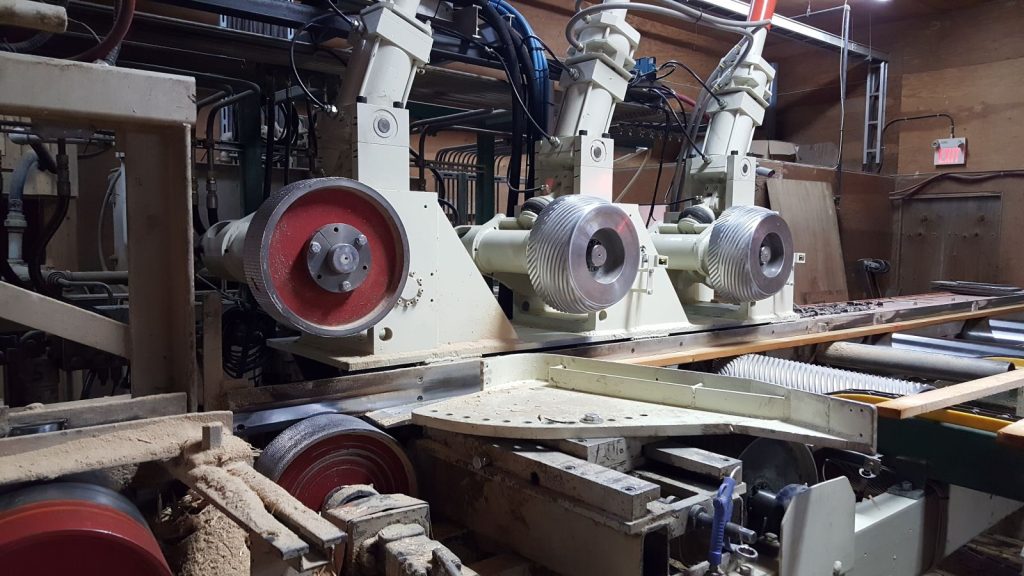

A great example of this is our long-standing partnership with Crabbe Lumber in New Brunswick, where several key retrofits have been successfully implemented over the years.

2017: Gilbert’s team installed feed table improvements and two new pineapple systems, enhancing lumber feeding and overall line flow.

2018: We removed all hydraulic components from the planer and retrofitted Gilbert Electric Drives. This transition brought multiple benefits:

- Reduced maintenance

- Higher operating speeds

- Lower energy consumption

2022: Crabbe Lumber took the next step by installing the Gilbert Automatic Cutterhead Positioning System. This upgrade has:

- Increased planer efficiency

- Significantly reduced downtime

- Improved operator safety

- Enhanced lumber grading through more precise settings

Mr. Crabbe shared:

These upgrades really helped improve our planer performance at lower costs over time. Smaller investments, with rapid paybacks!

We’re proud to support Crabbe Lumber in optimizing their planer operations and achieving long-term performance improvements.